ephect

Donating Member

- Joined

- Jul 27, 2006

- Messages

- 5,970

- Reaction score

- 15,747

- Points

- 113

- Location

- Melbourne

- Members Ride

- VS Acclaim V6

*** Disclaimer: For entertainment purposes only ***

The title won't be updated, and I'll avoid posting certain words, please respect this when posting replies. I wont hesitate to remove my content from the thread. You will not find any links to software either, nor will i post them, don't ask.

I share here only for your information, inspiration, and entertainment purposes.

This one has been in the making for the past 4 months in prep for Xmas and one of my proudest accomplishments to date. It's taken a lot of blood, sweat and tears getting it to look and function as close as possible. I've also unlocked some new programming skills

I found some threads relating to emulation software with lots of dead links. Those threads were enough to fuel my curiosity, if i could get it working, my parents Xmas present was locked in.

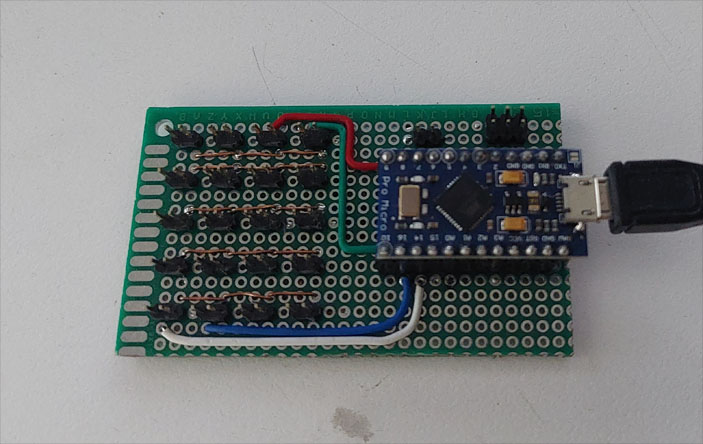

After some long nights searching, I found it. I had no idea if it was going to work or if I was going to be able to figure it out. Over the next month I checked each game and moved the non-working ones to clear up the clutter. The emulation software was clunky but worked. No pics of software until later. This emulator has set keyboard keys with no way of changing them, ruling out normal joystick or button controller boards, so i built one using arduino. Combination of button matrix with LED outputs and keyboard keys

Once the emulator and games were good, I focused on the front-end to make it pretty. I found the suggested frontend suggested in my searches and it was easy to add games, but it was very limited in visuals and menu, and hated it. CoinOps to the rescue. The Dev team has been making massive headway in speed and visual improvements in the arcade scene. Of course, there was nothing based on my project.

Queue the next month tweaking the layouts, finding and creating media and logos for the menu system and integrating the emulator. Testing, tweaking, testing, tweaking.

The title won't be updated, and I'll avoid posting certain words, please respect this when posting replies. I wont hesitate to remove my content from the thread. You will not find any links to software either, nor will i post them, don't ask.

I share here only for your information, inspiration, and entertainment purposes.

This one has been in the making for the past 4 months in prep for Xmas and one of my proudest accomplishments to date. It's taken a lot of blood, sweat and tears getting it to look and function as close as possible. I've also unlocked some new programming skills

I found some threads relating to emulation software with lots of dead links. Those threads were enough to fuel my curiosity, if i could get it working, my parents Xmas present was locked in.

After some long nights searching, I found it. I had no idea if it was going to work or if I was going to be able to figure it out. Over the next month I checked each game and moved the non-working ones to clear up the clutter. The emulation software was clunky but worked. No pics of software until later. This emulator has set keyboard keys with no way of changing them, ruling out normal joystick or button controller boards, so i built one using arduino. Combination of button matrix with LED outputs and keyboard keys

Once the emulator and games were good, I focused on the front-end to make it pretty. I found the suggested frontend suggested in my searches and it was easy to add games, but it was very limited in visuals and menu, and hated it. CoinOps to the rescue. The Dev team has been making massive headway in speed and visual improvements in the arcade scene. Of course, there was nothing based on my project.

Queue the next month tweaking the layouts, finding and creating media and logos for the menu system and integrating the emulator. Testing, tweaking, testing, tweaking.